Past online event recordings

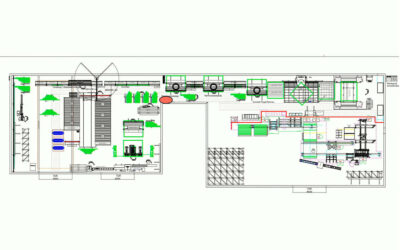

Plant concepts

Welding

Cleaning

Cutting

Milling & Drilling

Screw units

Metal mount & assembly sash/frame

Handling equipment

Logistic & automation

Stop- & measuring systems

Additionals & special machining

Interviews

Recordings plant concepts

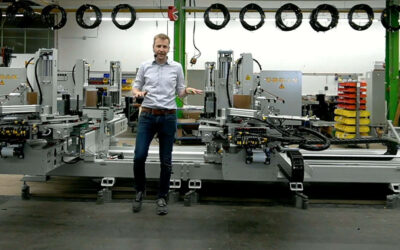

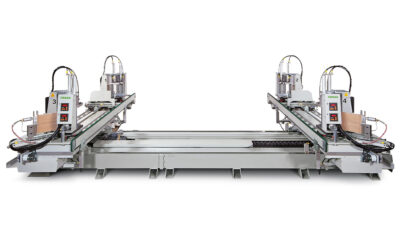

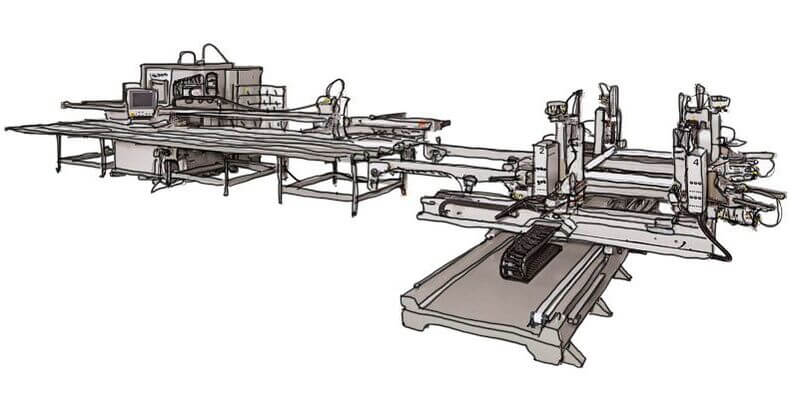

Horizontal production centers for PVC window profiles from URBAN in attractive packages. The clearly arranged control components guarantee simple and user-friendly operation.

Single Line AKS 6250-SV 430

New welding and cleaning line

New welding and cleaning line

Special sashes in progress

CUT welding in new dimensions plus high-tech storage system afterwards

AKS 6600-6/8 head + puffer system + SV 800

AKS 6600-6-8 head in U-turn with SV 800 and manual loading

AKS 6600-6-8 head in line with SV 800

Welding and cleaning in a retro look

Singleline production in the smallest of spaces live at the customer’s premises

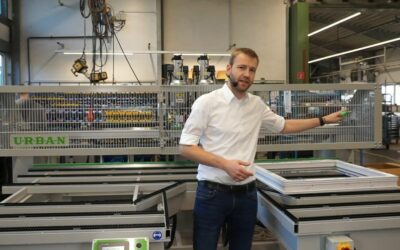

Smart and optimized window production – live at customer

High end window production – live at customer

Modern weld and cleaning

Recordings welding

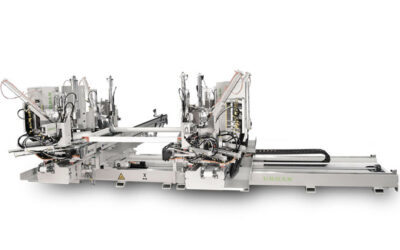

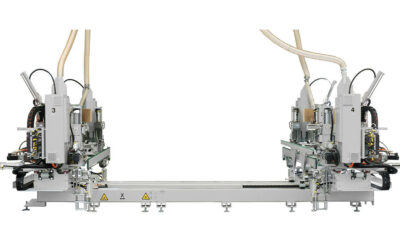

For more than 50 years, URBAN’s core competence has been the manufacture of plastic welding machines for welding heating elements for PVC window profiles. The customer can choose between one and up to eight welding heads. Basically, all Urban welding machine models have a uniform and solid basic construction.

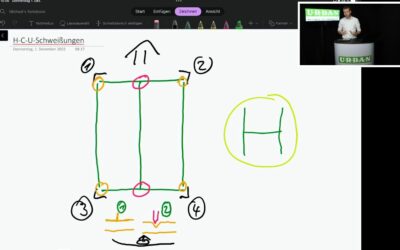

H,C & U-welding

AKS 4310 – default

AKS 6910 Vario – Live in production at the customer

AKS 6600-6/8 head

AKS 6600-4 head / side discharge

Corner test 4.0 – Push

AKS 4310 – TWL

AKS 6910 – Vario / Innerstop – Combination

Inline-welder AKS 5550-4

Welding machine AKS 6350 – Vario

AKS 1860 vertical 4-head allrounder

AKS 9600 in production – live at customer

Modern welding of window profiles

The world of 1-head welders – AKS 1150

Corner test 4.0 – Pull

Recordings cleaning

Weld bead cleaning machines from URBAN allow the efficient processing and cleaning of PVC-U window profiles after the welding process. The right machine is always available for every application and every production requirement. The tool positions can be freely selected for all models and the tooling can be customized on request.

Recordings cutting

Precise cutting to size is the most important prerequisite for the further quality of a window. This sets the course for how precisely the subsequent processing steps can be carried out. All machines in the cutting area naturally meet URBAN’s high quality standards and have a uniform, modern and robust design.

Recordings Milling & drilling

Whether frame or sash, tilt and turn or sliding door, drilling and milling are also important parts of the production of these elements within a window production and are therefore an important part of the URBAN product portfolio. These handling machines complement certain areas of your production in every respect and are therefore available for flexible use by any user.

Recordings screw units

Semi-automatic and automatic screwdrivers from Urban complement the production flow of industrial window production. The screwdrivers from URBAN enable user-friendly and efficient execution of the screwdriving work.

Recordings Metal mount & assembly sash/frame

An essential part of PVC window production is the assembly of components and fittings. Among other things, the metal fittings are fitted in this stage of production. URBAN has the right device for every customer requirement and every budget in the hardware assembly product group.

Recordings handling equipment

Operating equipment is a more than useful addition to a PVC window production process. URBAN also offers a wide range of accessories for the installation of window elements, transportation and storage of PVC profiles or accessories. Various tilting tables complete the range. The complete range of factory equipment from URBAN is well thought out and completes PVC window production in an efficient manner.

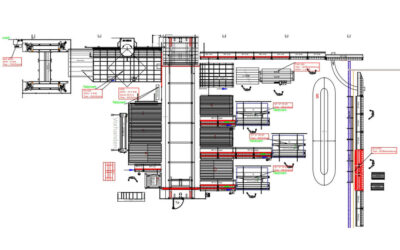

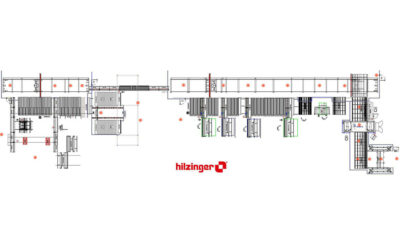

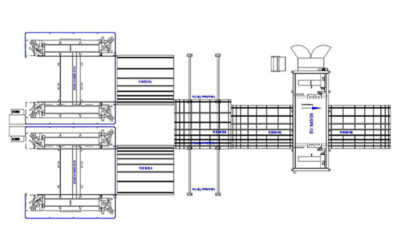

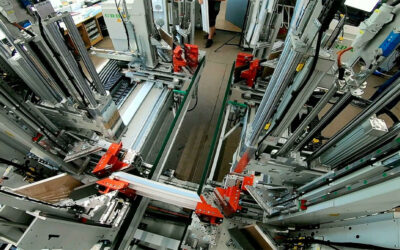

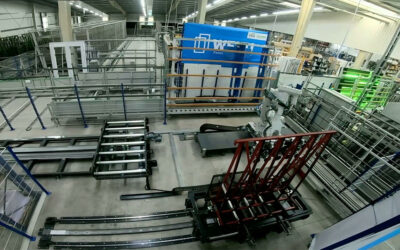

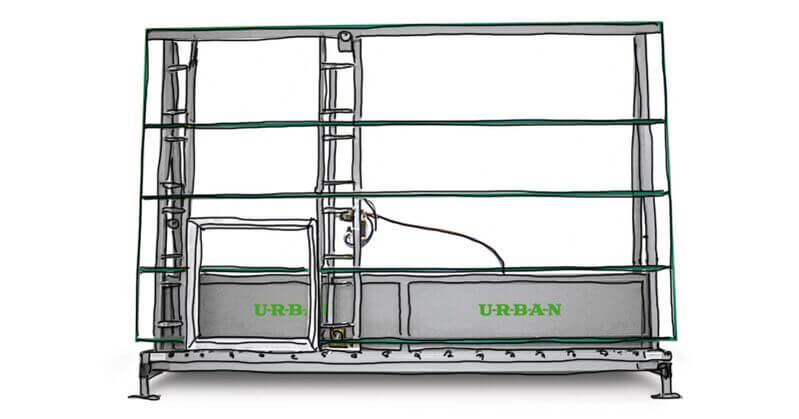

Recordings Logistic & automation

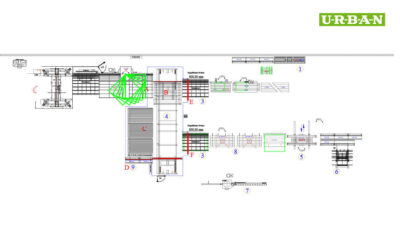

In addition to bar processing, welding and plastering the profiles, internal logistics are becoming increasingly important. The aim here is to optimize the production process and automate the merging of window and glass elements in the logistics area. URBAN can offer a comprehensive range of automatic transport conveyors, buffer racks, allocation systems, loading and unloading stations including the corresponding process optimization control (software).

Aluminium-windowproduction live at customer

Welding-Cleaning-Line in L-form with downstream manual destacking

Horizontal element puffer system

Shuttle systems in time lapse

Logistics rocks

Logistik in new dimensions

Vertical sash puffer

Special machines for special customers

The latest technology in glass automation live at the customer’s premises

Puffersystem for finished windows – live at customer

Recordings stop & measuring systems

Depending on the window model, the PVC profile bars must be further processed before or after the welding/plastering process. Instead of individual machines for a wide variety of processing sequences, fully automatic profile processing centers from URBAN are also available. Here, a wide variety of processing operations can be carried out with just one machine as required.

Recordings additionals & special machining

URBAN also has the perfect addition for your production line. Supplies for optimum welding results, milling cutters for clean contours or extraction systems for reliable chip extraction.